|

VIRTUALFIELD TRIP TO THE KEWEENAW PENINSULA, MICHIGAN - MINING HISTORY (1880-1920)

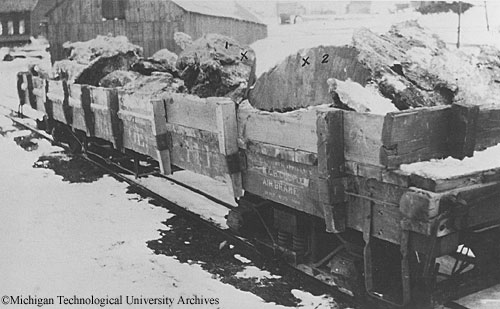

The mining of copper in the 1880's became even more of anindustrial enterprise when the conglomerate lodes and amygdaloidal rocks weremined. Even though these were of lower grades, efficiency improvements in miningmade the recovery of copper from these rocks economic. The Quincy mine was beingworked before this period and was the first mine to be successful in mining theselower grade ores. These rocks provided a more predictable source of copper ore than were available in the fissure mines.Around 1900, advances in mining technology, and the professionalism of the minemanagement had made the job of mining into one that could be handled byrelatively inexperienced laborers. The history of copper mining in the area isintimately tied into the Calumet and Hecla company (C&H). This was the largest miningcompany in the area and produced the bulk of the copper mined. If the dividendspaid by the Calumet and Hecla were not included in the totals, the investors inmines in the district would have just broken even. In the early part of the1900's, production in the district was controlled by four groups of investorsfrom the eastern United States. Calumet and Hecla was run by Shawand Agassiz which controlled 40% of production. Paine and Stanton ran CopperRange with 30%, Bigelow ran a number of mines which produced 20%, Mason was theprimary stockholder in the Quincy Mine which produced 10% of the total districtproduction. Prior to 1880, all the drilling was done by doublejacking. This required a team of two men, one holding and turning the drill toolwhile the other hit it with a six pound sledge hammer. The short holes ( usuallythree feet or less) were loaded with black powder. The transition from handdrilling to the use of compressed air drills went smoother in the Keweenaw thanin many other mining districts. The mine owners made it economicallyadvantageous for the miners to use the air drills and phased them in over a period of twentyyears. Oftentimes in the more economically marginal areas of the mines, the costof running compressed air lines exceeded the costs of hand mining, so mining wasstill done by hand drilling. There alsowas less of a problem with silicosis in the miners than in many other districts.The use of cooling water incorporated into the drills lessened the dust problemthat was experienced when the drills were first used. The mines initiallyconverted to some Rand drills which required two men to operate. When the ownersconverted to one man drills from Ingersoll-Rand, the miners did not want to usethis technology. The Cornish miners were the first major group ofimmigrants to come to the mines and their experience in mining soon led them tocontrol much of the mining operations. In Cornwall in the 1700's, there had beenmuch advancement in the art of mining as deeper workings led to greater use ofsteam power for hoisting and pumping. The advent of black powder for blastingthe rock also changed the nature of mining. The Cornish industry had relied onthe miners as independent contractors. On the day of the "set", minemanagers put the work out for contract bidding. There were two types of mining"tutwork" - which was the sinking of shafts and drifting throughunproductive rock, and the mining tributors - who mined the ore from stopes.Success in mining required that the miners be able to do up to six months ofwork and decide how much they were able to bid to get the work done and make aprofit. The adventurers had to be able to get a rough idea on the tenor of theore, how much it would cost to mine and sort the ore, and what the ore wouldbring in profit since they were paid a percentage of the value of the ore. Thiscreated a group of highly skilled miners who understood a broad range of topicson the issue of mining. During the mid 1850's there was a severe depression inthe mining industry in Cornwall, so many miners emigrated to Canada and theUnited States. The miners typically had to pay for the supplies used in the miningprocess; candles, powder, fuse, and drill steel. Hoisting rock from the mines usually began as a manpowered operation. Two men could lift 1-2 tons of rock from a depth of 100 feet perdays work. When the mine grew to a larger size, horse powered whims were used toraise the rock from the mine. Most mines eventually converted to ( and ones withbig plans started out with) a steam powered hoist to raise the rock to thesurface. Initially, there was a lot of handling/sorting of rockin the combination shaft/rock house. Over a period of time, this operationbecame more efficient as gravity was used to replace muscle power. As the ore was brought to the surface, waste rock couldbe dumped in an area where it was taken directly to the waste rock dump. Orewould be dumped over two grizzlies ( grates made with iron rail). The largestrocks ( which would not fall through the grate) would be fed into a large Blake jaw crusher.The output from this crusher plus the rejects (oversized pieces of rock) from the second grizzly would be fed into a smaller Blake crusher. The materialfrom this crusher and the material that went directly through the two grizzlieswould go into an ore bin. Ore was gravity fed from the ore bin into railroadcars for the trip to the stamp mill. Any large pieces of native copper would berun through a large drop hammer to remove any country rock and was sent directly tothe smelter. As time went on, the miners tried to keep from having to hoistwaste rock and tried to dispose of it within previously mined areas (stopes) underground( it also helped to support the mine openings). The first trains in the area were constructed in the 1860's toconnect the mines with the stamp mills and supply docks. In the mid 1880's the first trains fromthe Midwest were connected with the local tracks and the isolation in the winterwas lessened. The mills primarily used stamps for crushing the oreand separating the copper from the rock. They did try to use roller mills tobreak the ore and although they were more efficient at breaking the rock, theywere also more prone to breakdowns. Initially, Cornish stamps (basically a largemortar and pestle) were used. Thesefeatured cams to lift the stamp head and used gravity for the drop force. Latersteam stamps were developed which directly connected a steam driven piston withthe stamp head. This allowed steam to power both the lifting and the dropping ofthe stamp. Where the first stamps could process 1-2 tons of rock per day, thesteam powered stamps eventually could break up to 750 tons of rock per day. Over the winter of 1913, the Quincy mine converted to oneman drills. During the winter there was less union agitation. When summer came,there was a massive strike as the mine owners attempted to introduce the newtechnology and fire workers. There had been relative labor peace in thedistrict, but these developments led to an increase in membership in the WesternFederation of Miners. From a start in November, 1908 the union membership hadgrown to 7,000 members by the summer of 1913. The strike started on July 23, 1913, but by themiddle of August some mines were back in operation. On December 24, at a partygiven for the children at the Italian Hall in Calumet, someone yelled out"fire", causing a stampede and the deaths of 74; 60 of them children. The strike was over by April1914. Many of the miners left the area and moved to Detroit to work for Ford inthe automotive industry. Like many other occupations such as cowboys with rodeosand lumberjacks with logrolling and sawing contests, miners also competed in contests of their skills. The primary contests were for rock drilling, eithersingle jacking (one man) or double jacking (two man teams). The judges imported Vermont granite and timedthe drilling to a particular depth. Muckers (men who shoveled the broken piecesof ore into mine cars for transport to the shaft) also competed in contests(they would shovel a couple of tons of rock from a 6x3x2 foot bin). The town'ssocial life revolved around a number of fraternal organizations, fire companies, and ethnic religiousgroups.

|

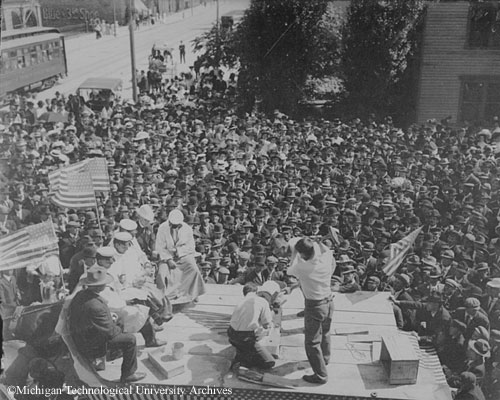

Copper miners drilling contest of 8/30/1912 between Calumet and Butte, Montanaminers. The miners are using air drills on blocks of granite that areapproximately four feet thick. They are using wooden frames to provide supportfor the drills (active drilling on left station). Photo courtesy Michigan Technological Universityarchives and Copper Country Historical Collections Reeder negative Z 796-A.

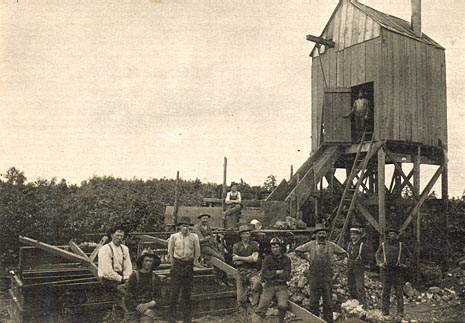

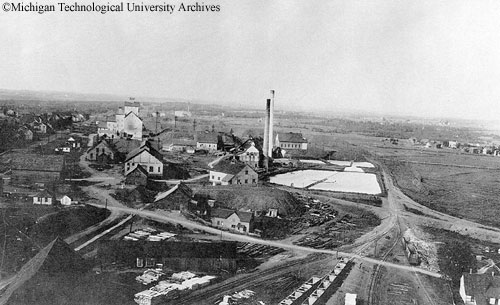

A mine near Hancock.

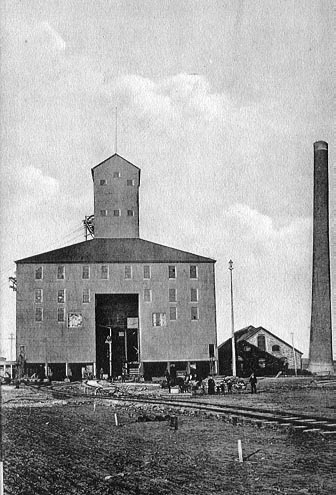

Red Jacket shaft house, Calumet. This shaft was unusual in that it was verticalinstead of inclined (these followed the dip of the ore bearings beds). This mineshaft was sunk to mine an area of the Calumet mines and keep it separate fromtheir other mines in the area. Fires had closed the main C&H mines for significantperiods of time, and this shaft was an insurance policy against completeproduction loss due to fire. Therewere specialized skips for removing rock from the mine, taking men into and outof the mine, taking supplies and equipment into the mine, and for dewatering themine ( some mines did use pumps for this purpose, but the drier mines could usea skip for water removal). Some of the original and smaller mines used horsepowered whims for hoisting, but most operations relied on steam to power thisequipment.

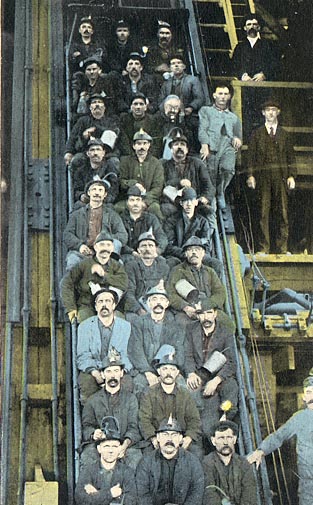

Miners on mancar just up from the Quincy mine. The shafts were inclined so that amancar rather than a cage ( like an elevator - used in vertical shafts) were used to take miners down into the mine. Minersused candles or oil lamps to provide light underground during this period (later, they used carbide or electric lamps). Time was transition from"soft" hardhats to more rigid ones. The candles were often attached tothe hats with clay.

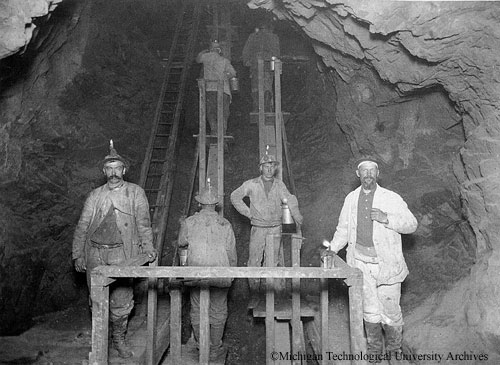

This is a drift in the mine. Note the large size of the timbers supportingthe roof of the mine. The mines reached a vertical depth of 6000 feet and largetimbers were necessary to support the large pressures wanting to close theopenings. The angle of the back (roof) follows the dip of the ore bodies in the mines.Trammers would push ore carts along the rails between the stopes where the orewas being mined and the shaft (it was cheaper to hire men to push the ore cartsrather than using mules or locomotives).

|

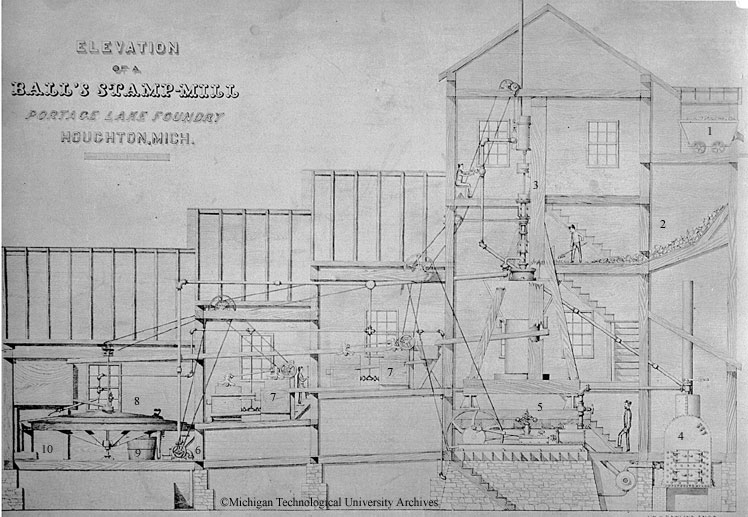

| Portage Lake Foundry and Machine shop, Sheldon, Wanger & Cleves, Proprietors.Mills such as this were often built into hillsides. Gravity is used to feed theore through the various processes. Ore was brought to the mill by train (1) and dumpedinto the building (2). It then was shoveled into the steam stamp (3) to reducethe ore to a size of 1-2mm. Steam was generated by a boiler (4) that providedpower to the steam stamp, to a stationary steam engine (5) that provided all ofthe mechanical power for the mill, and a water pump (6) to provide the waterneeded for the processing. Power from a stationarysteam engine was distributed throughout the plant via leather belts and pulleys.Ore from the stamp was then processed by jigs (7), which concentrated largerpieces of copper that had not been reduced in size by the stamp (copper ismalleable, and larger pieces would not be decreased in size by the stamp). Theseparation of the sand sized particles of ore was done on a sand wheel (8). Thisalso allowed the copper to be separated by the difference in specific gravitybetween the copper and the waste rock. The concentrate of copper ore ( whichwould run about 60% copper was then loaded into barrels (9) for shipment to thesmelter, while the waste rock was disposed into one of the lakes (10). Thisprocessing led to losses of about 25% of the copper originally contained in theore. This method was not very efficient in concentrating copper if the copper inthe ore occurred as small grains. Later, the more efficient Wifley tables wereused to replace the sand wheel. Photo courtesy Michigan Technological University archives and Copper CountryHistorical Collections. Negative 02708.

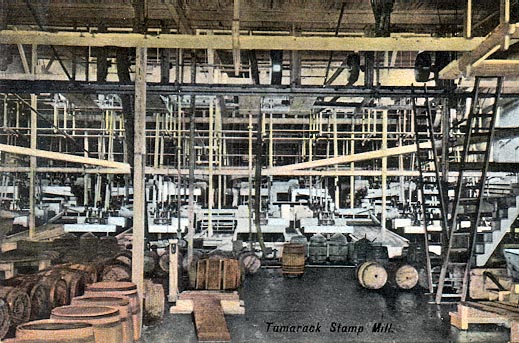

Tamarack stamp mill. The ores were crushed by the stamps and concentrated onthe inclined tables (Wifley tables). Note the barrels that were used in shipping the ore. The ore processed by the stamps consisted of rocks up to 3 to 4 inches in size.As the stamps pulverized the rocks, when the size reached 3/16 of an inch, thematerial passed over the tables that used gravity to separate the copper fromthe rock ( native copper is much heavier than the volcanic rocks making up thegangue). The mined ore grade was between 1 and 5 % copper. Most of the minesconstructed stamps on the shores of the lakes in the area where they would haveaccess to water, a place to dump the waste rock sands, and easy access toshipping to the outside world. Various methods were used to separate the copperand waste rock. They all relied on the difference in specific gravity betweenthe copper and waste rock to separate them. The output of this process was toget the copper concentrated to 60% of the ore.

Smelter at Houghton. In the district, the smelter (a hightemperature furnace) was used to separate the native copper from the rock inwhich the ore was found. The concentrated ore was heated in the furnace untilthe ore became two immiscible liquids. The liquid copper is heavier than theliquid silicate melt that the rest of the ore formed. By tapping the furnace onthe bottom, the copper could be drawn off while the silicate melt could be drawnoff from the upper portion of the furnace.

Refinery. The smelting operations were primarily concerned with separatingthe native copper from the rock the ore was found in. Unlike other smeltingoperations which were required to free the copper metal from chemical compounds,this operation was used to reduce the amount of silicate rocks in the metal. The copper was melted and poured into molds to formingots, which were a convenient way to ship and sell the copper.

The ingots from the Isle Royale Mine in Houghton were loaded aboard steamer Juaniatafor shipment on the Great Lakes forfurther refining and fabrication. The copper from the district was known for itspurity and much of the copper found its way into the wire that was used for theelectrification of the U.S. The Great Lakes were closed to navigationbetween November and May, so the entire years shipping had to occur during thisperiod.

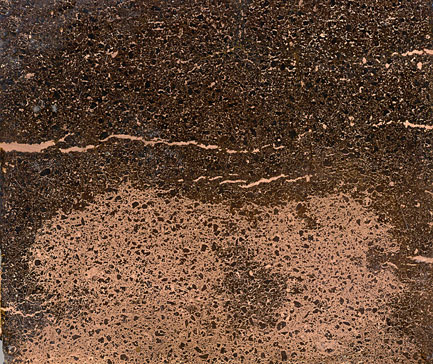

Copper replacing fire brick (15 cm across). Sample is from Calumet and Hecla smelter atHubbell. Fire brick was used to line the smelter furnaces to help protect thefurnace from being melted. Over time, the copper partially replaced the minerals in the fire brick. Thismaterial has been used as a lapidary material in the area. [Include:'../../../inc/footer.html'] |