The period after 1920 saw the mines enter into aperiod of decline. After the First World War, there was dumping of copper ontothe market, copper demand was down, and the western mines relied more and moreon open pit mining. Each pound of copper produced meant that there was one lesspound of copper to mine and the costs of mining kept increasing as the oredeposits increased in depth and the ore grades dropped. It was often cheaper for the mining companies toreprocess the tailings from earlier operations than to mine new ore. They kept active until the 1960's, but were ahigh cost producer of copper. Whenever the price of copper declined, the miningoperations would slow and some mines would close, never to reopen. In the area of milling, the companies started using the Wifleytables which captured smaller particles of copper. The mining companies also dredged the olderstamp sands which still contained about 25% of the original copper. These were thenground finer in ball mills (giant rotating cylinders with balls of iron tocrush the sands). They also used froth flotation which used chemicals and air toconcentrate the copper in the bubbles, which were then skimmed off from thewaste rock stream. Processes were developed to dissolve thecopper in ammonia and recover the copper from these solutions. The White Pine mine was first prospected in 1865. The finegrain size of the copper minerals precluded any development of the mine at thistime. Calumet and Hecla mined the property for native copper from 1909 to 1921.The Copper Range company outbid Calumet & Hecla in a 1929 sheriff's saleby $388.15 and obtained the mine. During the Korean War, they obtained a$68million loan to put the mine back into operation. They were able to use a roomand pillar method (since the deposit is relatively flat) to develop the mine. The White Pine mine was producing from1952 to 1995 when the smelter could not reach environmental standards. In 1997,plans to solution mine copper were also shelved due to environmentalconcerns. Itwas an unusual ore body for the district in that there was significant production of copper sulfides (primarily chalcocite) and the copper was found in the Nonesuch shale, aformation that was deposited after the lodes in the rest of the Keweenaw. Themine produced over 4 billion pounds of copper and 45 million ounces of silver. The other sulfide ore body in the area is in the Mount Bohemia area on the far north side of the peninsula. A number of copper sulfides are found in an igneous porphyry body. A number of attempts have been made to mine this ore, but none have been successful. The area is now a ski hill. Calumet & Hecla had attempted to stay in thecopper mining business by purchasing control of other smaller mines in thedistrict as well as exploration for other ore bodies on their properties. A strike in 1968,the saleof the Calumet & Hecla company to Universal Oil Products, and the lesser grades atgreater mining depths caused the shut down of the mines. In 1970, the companystopped the pumps on it's Centennial and Kingston shafts, and the last nativecopper mines shut down. A large percentage of the production in later years byC&H was recovery of scrap and reprocessing ofthe tailings from earlier mining. The stamp sands were recovered from Torch Lakewith the use of a dredge - later purchased by the Quincy mine ( It is still sitting in the lake).

Quincy #1 dredge on Torch Lake. Dredge sank on 1/15/1956.Photo courtesy MichiganTechnological University archives and Copper Country Historical Collections. Negative03808 from Louis Koepel / Quincy Mining Company. For present day view click onphoto above.

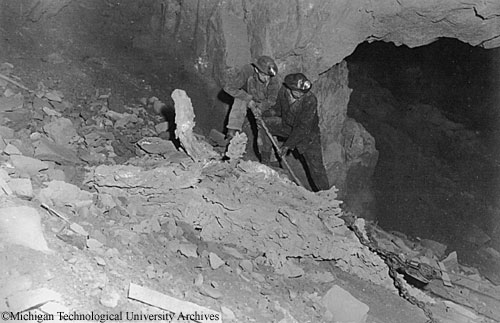

Even though mass copper was relatively rare, even in the later mining periodsome was found. Power equipment made handling the masses somewhat easier, but itstill required greater handwork than the normal ore.12th level of the Ahmeek mine, with the mass partially reduced. Photo courtesy MichiganTechnological University archives and Copper Country Historical Collections.Calumet & Hecla photograph collection MS-003 Box 25 #137.

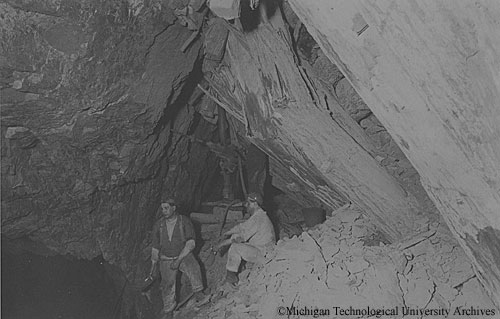

Calumet & Hecla #6 at the 62nd level stope. The extreme pressures at depthcracked timbers used to keep the stopes open. Photo courtesy MichiganTechnological University archives and Copper Country Historical Collections.Calumet & Hecla photograph collection MS-003 Box 25 #9

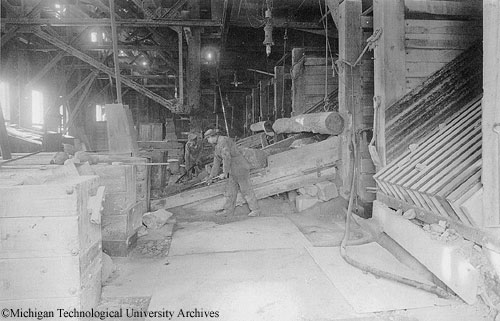

Tamarack #5 shaft - Rock house breaker floor. The rock house allowed rockbeing brought to the surface to be processed. Underground, the ore from thestopes was segregated from waste rock generated to tunneling to reachore-bearing areas so that they could be raised to the surface separately. Any waste rock could be shunted directly to rail cars for disposal on surfacewaste rock dumps which were located near the mine shaft. Ore from the mine was passed overthe grizzly (on the right) which allowed the smaller rocks to pass throughdirectly to the ore cars for transport to the mills. Larger rocks were fed intocrushers to the left. Any relatively pure pieces of copper were pulled off sothat they would not break the crushers and were sent directly to the smelter. Photo courtesy MichiganTechnological University archives and Copper Country Historical Collections.Calumet & Hecla photograph collection MS-003 Box 25 #124

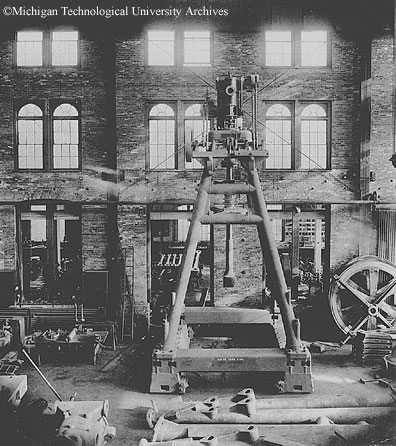

20x24 steam stamp. The steam powered cylinder was at the top of the machine. Thehead (on the bottom) would have a metal trough that surrounded it, and there would be anautomatic feeder for the ore. The pulverized ore would go on to further processingin jigs and sand wheels or Wifley tables. Photo courtesy Michigan Technological Universityarchives and Copper Country Historical Collections. Negative 05238.

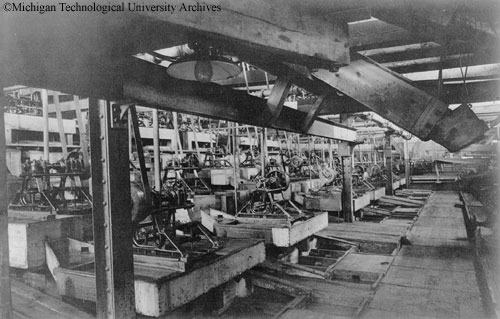

Osceola mill jigs. Jigs were used to separate larger pieces of native copperfrom the waste rock by gravity. Photo courtesy MichiganTechnological University archives and Copper Country Historical Collections.Calumet & Hecla photograph collection MS-003 Box 25 #316.

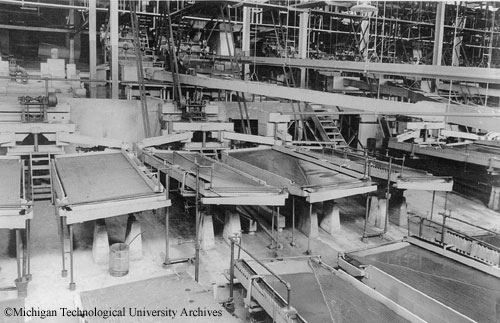

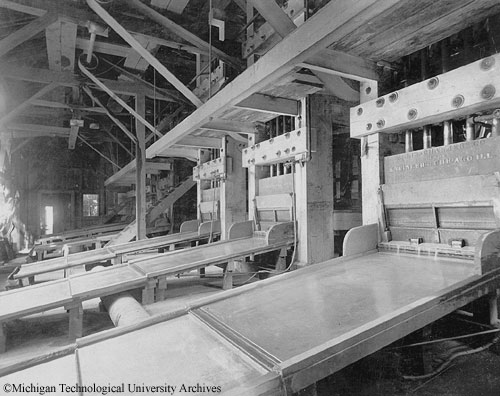

Wifley tables on the Ahmeek mine were used to separate native copper of arelatively small size (sand) from the waste rock. These replaced the earliersand wheels. Photo courtesy MichiganTechnological University archives and Copper Country Historical Collections.Calumet & Hecla photograph collection MS-003 Box 25 #296

Wifley tables? Photo courtesy Michigan Technological University archives and CopperCountry Historical Collections.

Calumet & Hecla smelter's electrolytic plant. Copper was purified bydissolution of the partially refined copper and electroplated on electrodes.Photo courtesy MichiganTechnological University archives and Copper Country Historical Collections.Calumet & Hecla photograph collection MS-003 Box 25 #332.

Caledonia mine on south end of range. Mine started in 1863 and is the lastactive mine on the peninsula (mining is for specimen material).

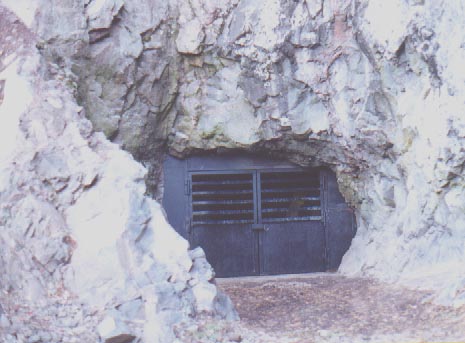

Nebraska mine. Slotted doors allow bats to enter and leave the mine (theylive and hibernate in the mine) while keeping people from entering (2001). |